Benefits of Using Lyobeads:

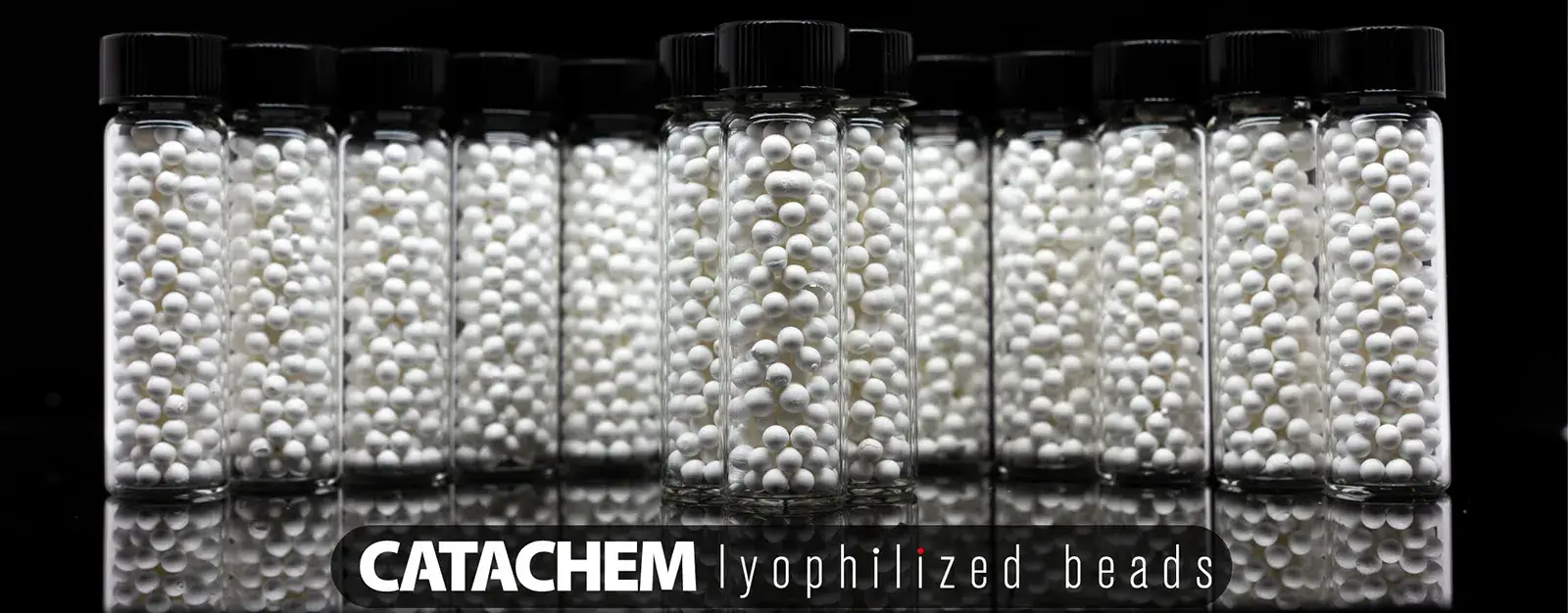

Lyophilized beads (sometimes called “lyobeads”) are a natural extension of the basic lyophilization process. Liquid beads start as uniform droplets that are floated over a bed of liquid nitrogen which freezes these droplets into circular beads. These beads are then collected and lyophilized in the standard way resulting in a container full of small uniform beads. These beads provide the material contained within them with all the advantages of a freeze-dried product with the added benefit of enhanced ease of use. Not only are these beads reproducible uniform concentrates of the freeze-dried product but they can also be handled and packaged with additional ease either as a single bead or a finite number of beads. Some of the key benefits and applications include:

1. Enhanced Stability:

Lyophilization removes water from the beads, reducing the risk of degradation or spoilage caused by moisture. This helps in preserving the stability of sensitive compounds, such as vaccines, enzymes, or biological materials, for longer periods.

2. Extended Shelf Life:

By eliminating moisture, lyophilized beads can have an extended shelf life compared to non-lyophilized forms of the same material. This is especially crucial for preserving the potency and efficacy of sensitive substances.

3. Easy Storage and Transportation:

Lyophilized beads are lightweight and typically more stable, making them easier to store and transport. They are less prone to damage during handling and shipping compared to liquid or non-lyophilized forms.

4. Reduced Contamination Risks:

Lyophilized beads are often more resistant to microbial growth and contamination due to the absence of water and to some degree their circular shell-like shape. This helps maintain the integrity and purity of the material, especially in biotechnological applications.

5. Versatile Applications:

Lyophilized beads can be customized in size and composition to suit specific purposes, making them versatile for different uses. A usual bead starts with a liquid volume of 10 to 30 microliters. The resulting bead from a 20 micro liter volume often produces a bead weighing around 3.5 mg with a diameter of around 3.5 millimeters.

6. Improved Reconstitution:

Like most lyophilization products a lyophilized bead, upon reconstitution, often returns very quickly to its original state, maintaining its structural integrity and functionality. This ensures consistency and reliability when reconstituting the material for use.

7. Better Solubility and Dispersion:

In certain cases, lyophilized beads can have improved solubility characteristics compared to their non-lyophilized counterparts. This can lead to better dispersion and dissolution properties when reconstituted, aiding in their application.

8. Research and Development Benefits:

For researchers, apart from their enhanced ease of use lyophilized beads offer standardized and stable forms of compounds, allowing for more consistent experimentation and analysis without concerns about material stability or degradation.

These benefits make lyophilized beads a valuable form for storing, transporting, and utilizing various sensitive materials across many different industries.

How Can We Help You?

If you are looking to place an order, request technical help or ask questions about us, get in touch today!